URN-2022

A visually imposing reminder of Status and Mortality.

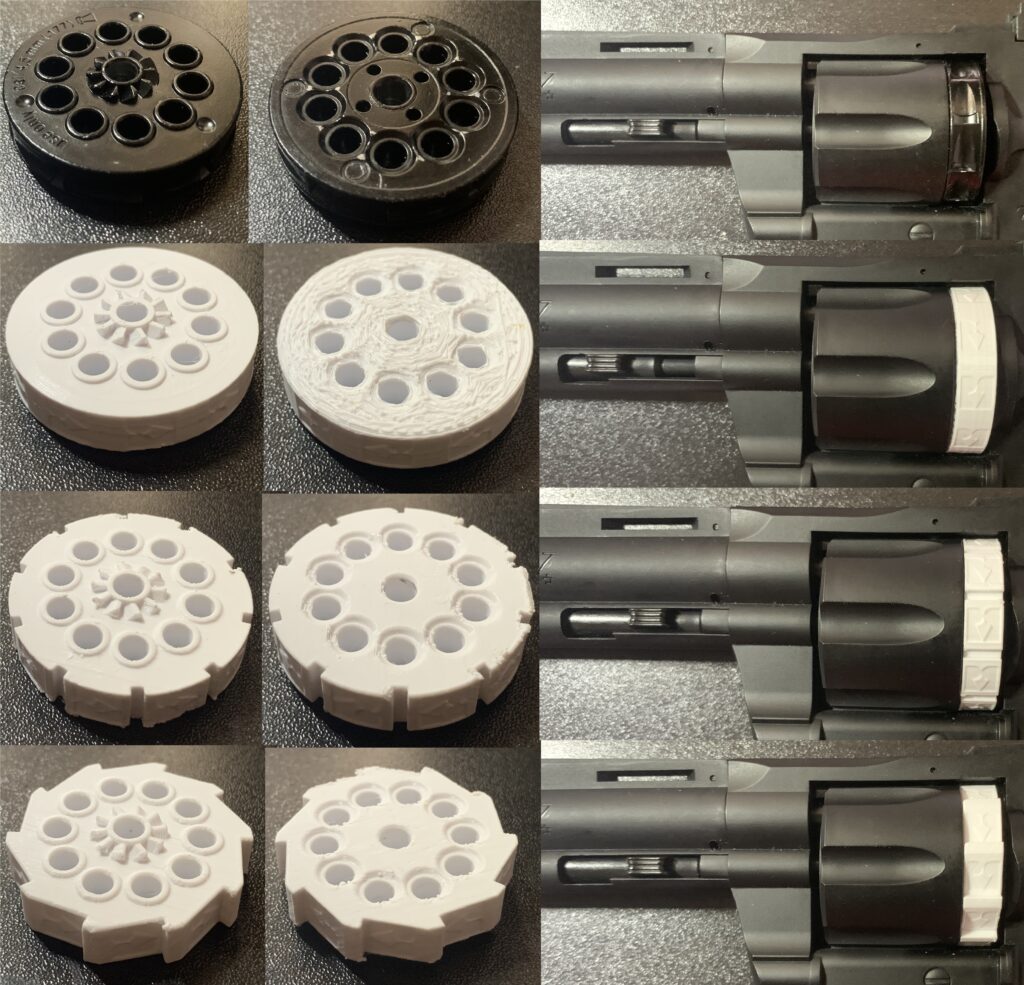

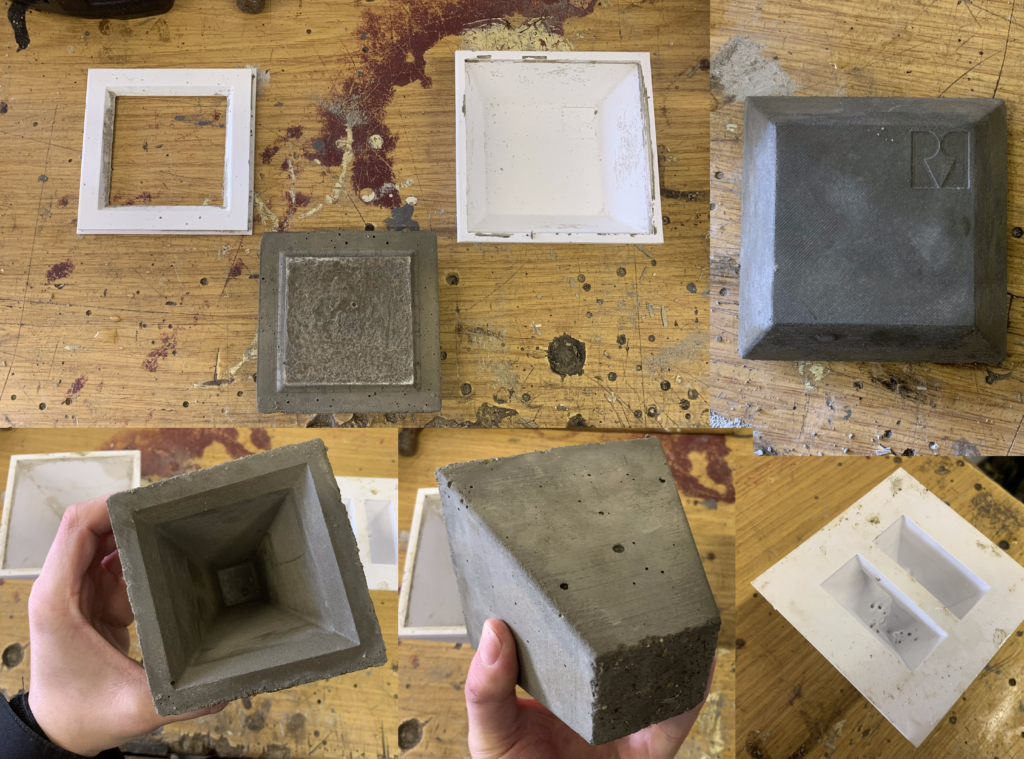

A development from single to two-part 3D-printed moulds.

MORTALITY

Memento Mori – Remember you must die. The URN-2022 is a visual reminder that will one day perish. This piece is designed to encourage reflection on one’s life, its fragility, and what legacy one can leave behind.

STATUS

The URN-2022 is an Urn for those starting out in life. It does not have many luxuries or lavish design features. It is simple and utilitarian, and cheap.

“What is the point of being alive if you don’t at least try to do something remarkable?”

– JANET MORRIS

THE URN PROJECT

The URN PROJECT is a personal project to me, Max. I will design an urn for myself every few years or every time I have a life event; in order to reflect on and examine my relationship to status. The point at which you die is the point at which your true status is realised, the first time in your adult life that everything you are will be only what others think of you. Your status impacts your funeral, your burial, who remembers you and what they remember you for, and your legacy. I hope the urn can act as a sober reminder of both my mortality and status throughout life.

This urn has been designed in concrete, as it is the material I’ve been falling in love with. There is no onus to make future urns out of concrete, they shall likely be made from whichever material I’ll be working with at the time.

Two Part Moulds

A DEVELOPMENT FROM SINGLE-PART MOULDS

Though the parts of the URN-2022 are very simple, they are slightly too complex for single-piece moulds due to their interlocking pieces and the pot shape of the lower piece.

As with single-piece moulds like the ones used for the ashtray collection, the shape is largely determined by the draft angle requirement. The smallest draft angle present here is 15 degrees on the lower part of the urn. This is the smallest I’ve gone with concrete casting so was somewhat of a risk. The top piece also has a fair amount of casting risk, due to having a flat surface at the top (of the mould) that act as a trap for bubbles in the concrete mix.

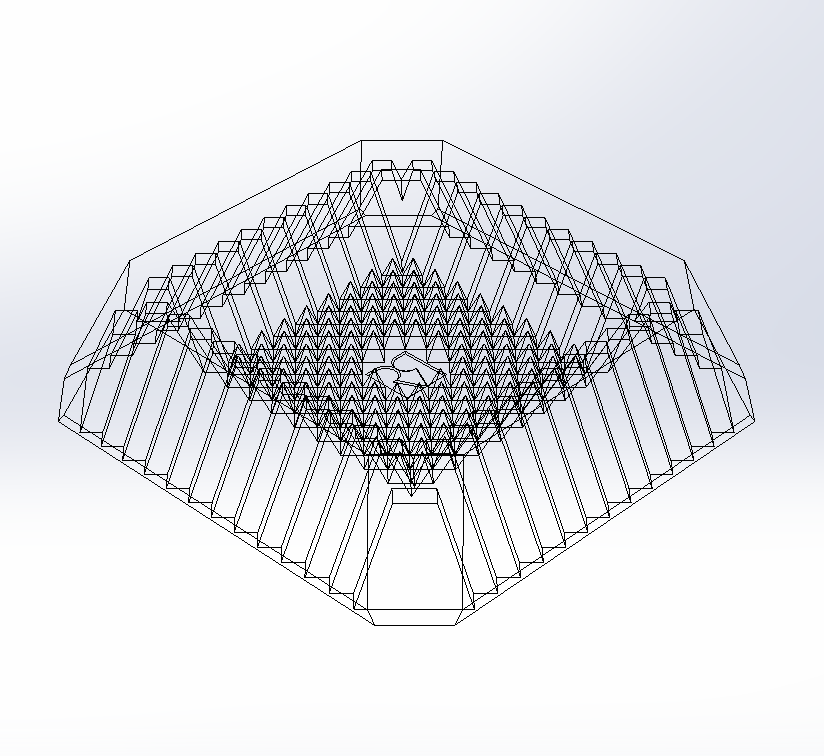

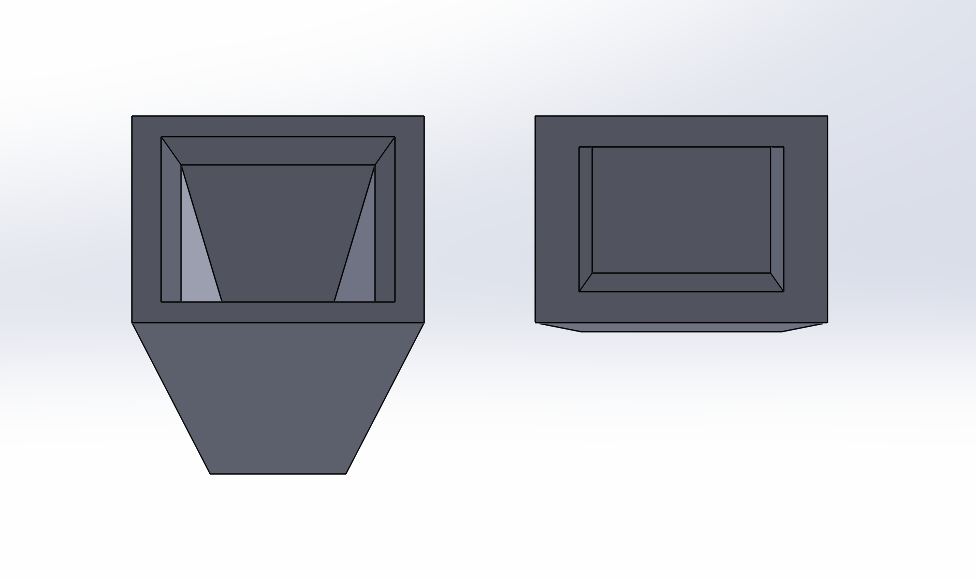

MOULD DESIGN

Moulds were designed to be simple to 3D-print and use. Though two-piece moulds could be used to make a completely enclosed space, this could be complicated to use so it was chosen to have one open face that the mould could be filled. This face is on the bottom of each of the pieces, meaning the urn rests on this open moulded face, meaning the face has to be crafted incredibly carefully to ensure the urn rests flat. Mould pieces are designed to be push-fit together and separated with a fine-edged lever. This should ensure mould release for at least one side of each mould, with draft angles responsible for ensuring release on the other halves.

Iteration 2

Review of 1st Iteration Outcome

Top Part – Top Row

The top piece came out perfectly. The mould halves separated easily and a great amount of detail was captured – especially on the exterior. The mould is fully reusable and perfectly functional for continued us as-is.

Bottom Part – Bottom Row

The bottom part had a few issues. Firstly, the concrete shrunk a lot while setting. This was due to a combination of mould leakage (minor) and the concrete having slightly too much water content. The interior mould also got stuck, necessitating billing water and a fork to deform the plastic enough to release (bottom right). Surface detail capture was good regardless, it was decided to redesign some mould pieces and make the next iteration with thicker concrete.

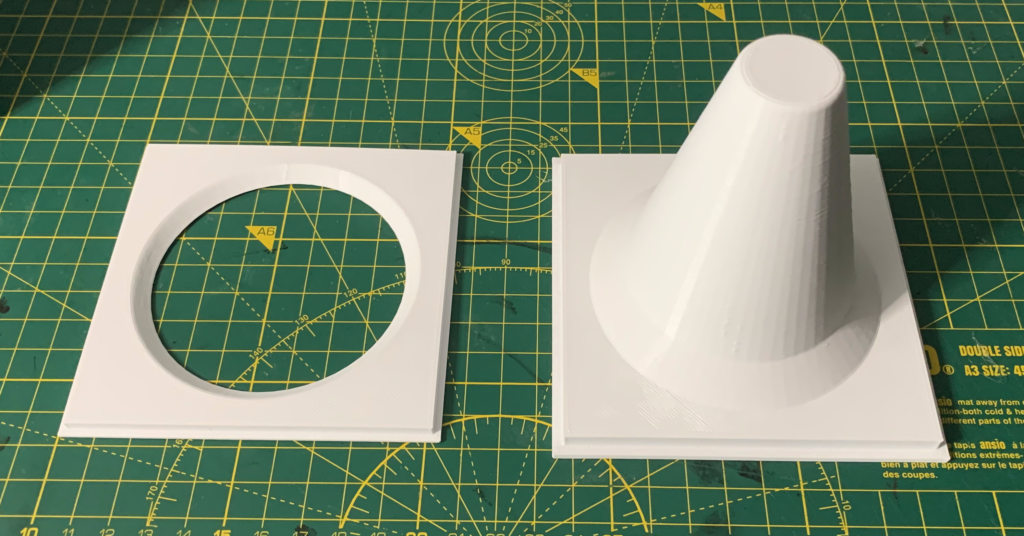

DESIGN CHANGES

The inner part of the bottom mould was changed, turning the inner cavity into a circular cross-sectioned shape. This should allow easier separation of the middle as there are no sharp corners and the mould can be twisted. The top piece of the top mould was changed to reflect this new lip shape. The outer pieces of both moulds are to be re-used.

Additionally, a spacer piece was made to mould indents for feet and a close-fitting rod was made to aid in demoulding the bottom part without compromising edge strength.

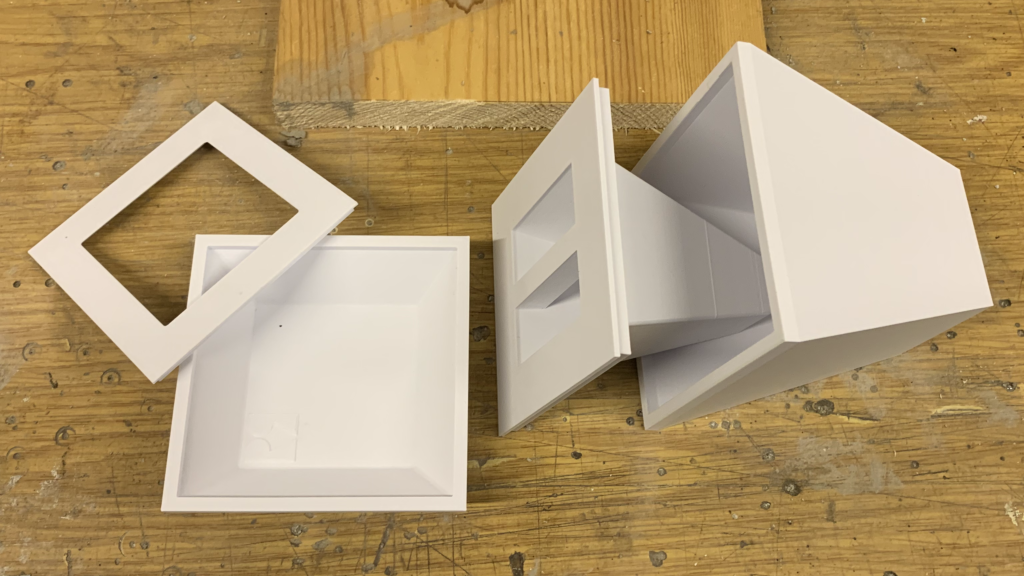

Review

Cracked Moulds but Good Outcomes

The mouls were not as reusable as expected. The impacts from removing a previous URN caused the outer mould to crack. Regardless, the URN worked great, and the pattern this formed was actually very nice.

The circular inner-mould worked better but still required a hot water aided release. This inspired me to reprint in Vase-mode, allowing the printer to generate a strong enough part that was sacrificially removed after each cast.

The feet came out great thanks to the tool printed to imprint them.

This was the final iteration of the URN-2022, iit now sits in my bedroom, doing its job.

Let’s work together on your

next design or engineering project

Contact us to discuss how we can best work together to achieve your desired results.