CASE STUDY: AIRGUN MAG

Attention to detail and honed CAD skills weaponised, to create drop-in replacements for an air-gun magazine, optimised for 3D printing.

It’s legal in the UK, as I am NOT making any firearms, just accessories; don’t worry.

RED FLAGS

Recently, I’ve become fascinated with 3D printed ‘ghost guns’, the sort that terrifies domestic terrorism watchdogs.

As guns are illegal here, customising and making parts for airguns is the best I can do. This endeavour is somewhat of a tentative dip into ballistics design, and I may find myself humbled.

The design will be on my Thingiverse if it survives testing. Please don’t kill yourself with it, plastics are brittle and shatter.

“What is the point of being alive if you don’t at least try to do something remarkable?”

– JANET MORRIS

Imitate to learn

ITERATIVE COPYCATTING

The value of a pair of cheap(ish) Mitutoyo callipers as an investment in your design skill is ridiculous. I use an analogue pair because I hate batteries and don’t trust electronics.

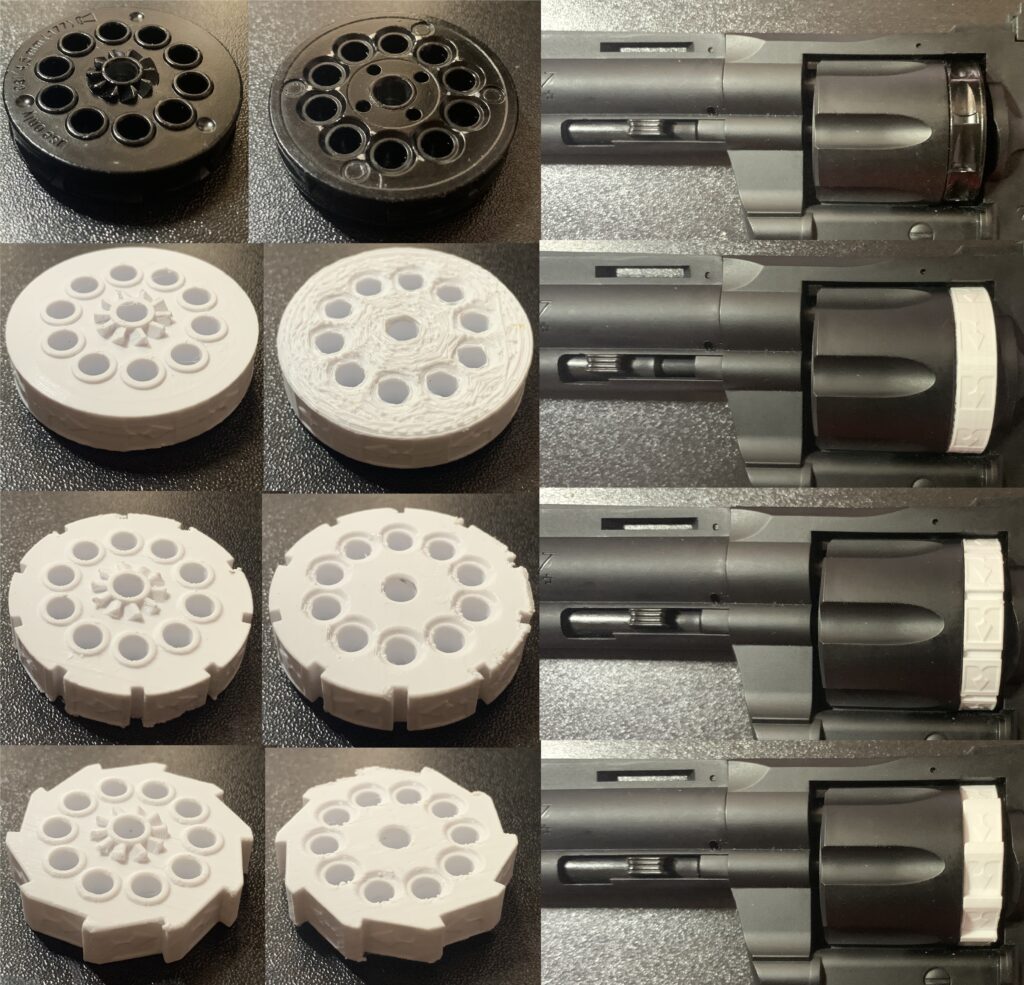

With V1, I aimed for a close imitation of the original magazine, using this design I found on Thingiverse as a reference for the bore size. The gear teeth worked straight away, but the bore was too small for the gins securing the pin to grip, and there was excess friction within the gun. I also thought printing on a raft would be a good idea but this failed to produce an adequate surface finish.

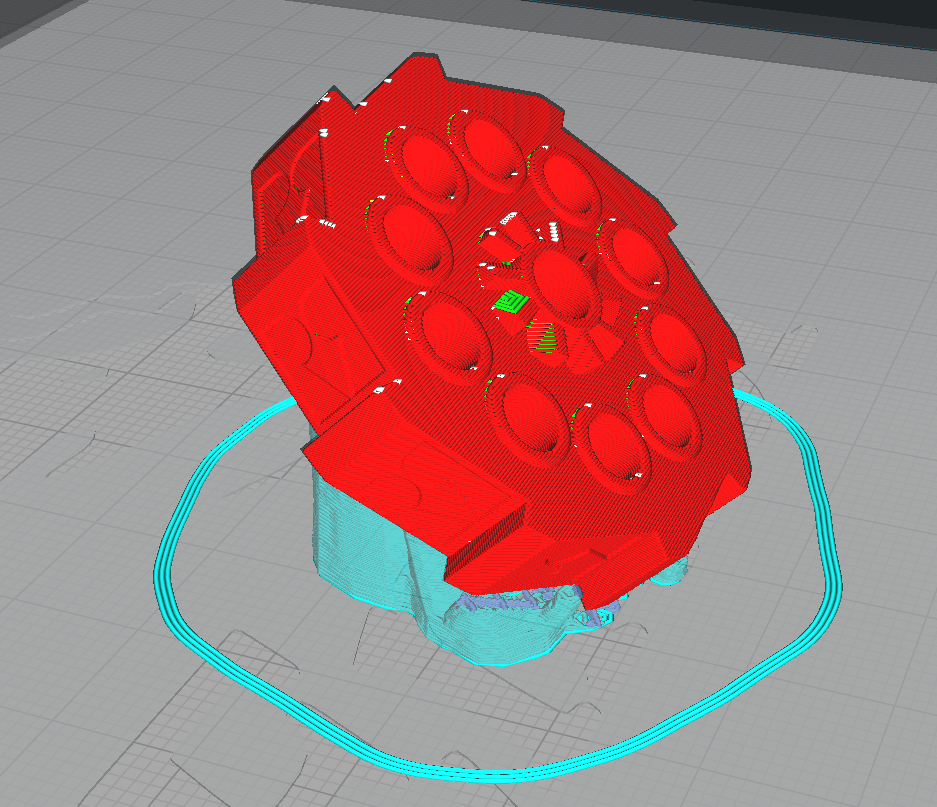

V2 of the design had the bore widened, and slots added to work with the gun’s trigger lock, which prevents the magazine from rotating further than it should when the gun is cocked; this did not completely eradicate the excess friction. The print setup was fixed by printing at a 45-degree angle from the print bed.

V3 is seemingly perfect, even more material cut away as the trigger lock is raised a lot of the time during operation, fixing the friction issue. Pellets test fit well into it and it turns so smoothly; the only part left to now do is the real testing…

Destructive? Testing

THE PROOF IS IN THE PUDDING

Now the design has been validated in the gun while unloaded, a print run of 5 in solid PLA+ is being produced to be tested.

If trying this yourself, eSun PLA+ is all I’d recommend using, its mechanical properties are exceptional compared with virgin PLA and its printability is very good.

This page will surely be updated below when I have shot things with these magazines and seen whether they survive.

Let’s work together on your

next design or engineering project

Contact us to discuss how we can best work together to achieve your desired results.